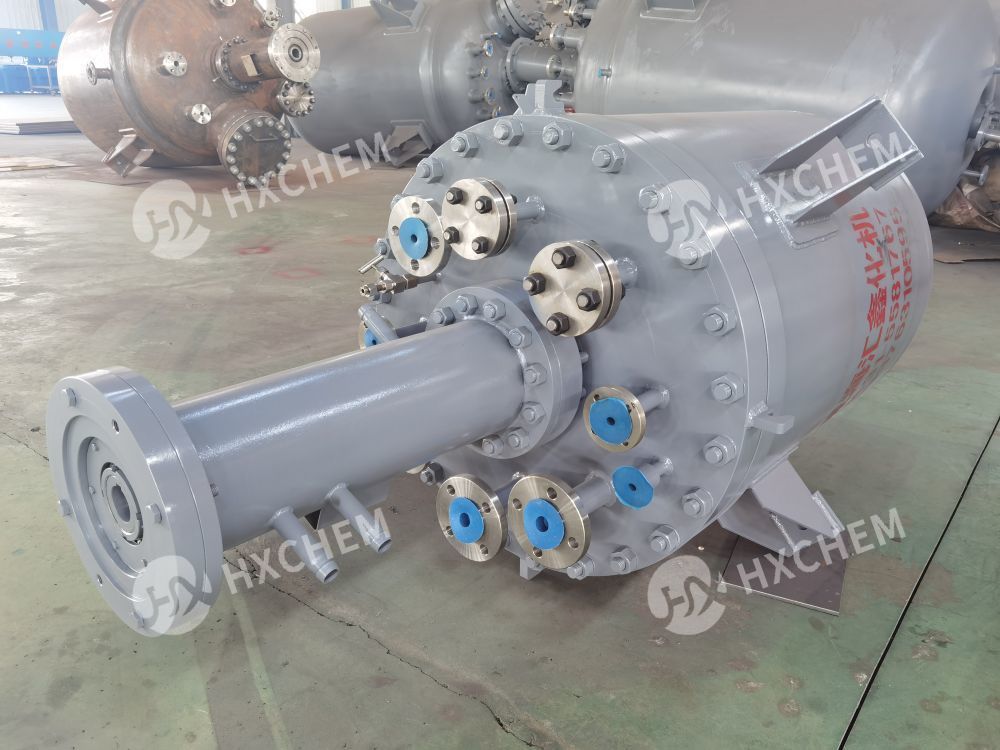

Industrial stirred hydrogenation reactor

Pang-industriya hydrogenation reactors ay karaniwang nagsasangkot ng isang tatlong-phase slurry, ang solid catalyst sa slurry phase at ang hydrogen bubble bilang ang gas phase. Dahil mayroong isang bilang ng mga hangganan ng bahagi, ang paglipat ng masa, at lalo na ang pagpapakalat ng hydrogen, ay isang napaka kadahilanan. Ang sistema ng paghahalo na ginagamit sa reactor ay lubos na nakakaimpluwensya sa koepisyent ng mass transfer ng gas-liquid transfer. Industrial hydrogenation reactors; hydrogenation autoclaves; Hydrogenation reactor; Hydrogenators; hinalo hydrogenation reactor

- HXCHEM

- CHINA

- 25 araw pagkatapos ng pagbabayad

- 10 SETs/MONTH

Mga Detalye

Catalyst Hydrogenation Reactors/ Hydrogenators

Ang HXCHEM ay isang solong solusyon para sa lahat ng kailangan mo para sa iba't ibang High Pressure Reactions tulad ng Catalytic Hydrogenation, Ethoxylation Hydrogenation, Polymerization, Chlorination, Alkoxylation, Ethoxylation, Alkylation, Amination, Esterification, Bromination, Carboxylation, Oxidation, Ozonization atbp. at iba't ibang mataas presyon ng mga reaksyong Gas-Liquid, Gas-Slurry o Liquid-Liquid mula sa laboratory scale, R&D, Pilot Plants hanggang sa Commercial Scale Capacities.

Kami ay tagagawa at supplier ng automated at manual, stirred at non-stirred High Pressure Reactors para sa mga kliyente sa R&D, Pharmaceutical, Bulk Drugs & Drug Intermediates, Petrochemical, Aromatic Chemicals, Agrochemicals, Fertilizers, Pesticides, Resins, Polymers, Paints, Food Colors at Mga Chemical, Dyes at Dye Intermediate Industries gayundin sa akademya.

Mayroon kaming pangkat ng mga highly qualified na inhinyero at propesyonal, na may malalim na kaalaman sa kani-kanilang mga domain. Nagbibigay-daan ito sa amin na gumawa, mag-supply at mag-export ng malawak na hanay ng mga produkto para sa aming mga pinahahalagahang kliyente.

Kami ay gumawa at matagumpay na nag-commission ng ilang High Pressure Reactors/ Hydrogenators / Autoclaves kasama ang Magnetic Drives, Nagawa din namin ang verv high flow rate catalvst filters para sa noble metal catalvst tulad ng Palladium (Pd/C), Platinum(Pt/C), RhodIum , Ruthenium atbp.

Ang sistema ng hydrogenation ay kadalasang nagsasangkot ng tatlong-phase na slurry, ang solid catalyst sa slurry phase at ang mga hydrogen bubble bilang ang gas phase. Dahil mayroong isang bilang ng mga hangganan ng bahagi, ang paglipat ng masa, at lalo na ang pagpapakalat ng hydrogen, ay isang napaka kadahilanan. Ang sistema ng paghahalo na ginagamit sa reactor ay lubos na nakakaimpluwensya sa koepisyent ng mass transfer ng gas-liquid transfer.

Kumuha ng higit pang mga detalye tungkol sa Hydrogenation.

Catalytic Hydrogenations, Industrial hydrogenation reactors; Industrial hydrogenation autoclaves; Mga dehydrogenation reactor, Three-phase catalytic hydrogenation reactor, Shaker Hydrogenation Apparatus, Sorbitol Production Hydrogenation Reactor, Continuous hydrogenation reactors industrial dehydrogenation reactor,stainless steel hydrogenation reactor,jacketed hydrogenation reactor, hydrogenation plants, Scale-up hydrogenation reactor, Hydrogenation reactor

Industrial hydrogenation reactors

Dami: 100ml-20000lits.

Presyon ng disenyo: maximum na hanggang 350bar

Temperatura ng disenyo: Hanggang 350 ℃

Paraan ng pag-init: Steam/ Oil/ Electric

Basang materyal: SS304, SS316 o iba pang mga haluang metal.

Catalytic hydrogenation reactors | Hindi kinakalawang na asero hydrogenation reactor | Mga halaman ng hydrogen

Mga tampok

Gas Induction Tech.

Gas Induction Tech. mula sa HXCHEM

Mas mataas na gas Hold-up at mass transfer

Fine dispersion ng hydrogen

Malaking Gas-Liquid na interfacial area

Recirculation ng hindi nagamit na gas

Unipormeng pagsususpinde ng mga solidong bahagi (hal., Catalyst)

Magnetic Couplings Driver

100% Pagbubuklod. Zero leakage. Mababang gastos sa enerhiya.

Iba't ibang modelo para sa volume: 100ml~50m3

Mahabang buhay ng paggamit ng mga bearings, mas kaunting oras ng pagpapanatili

Available ang buong vaccum/200 bar;

Nakatakda ang cooling jacket para sa paggamit ng mataas na temperatura.

Opsyonal na Mga Panloob na Fitting

Panloob na heating/Cooling coils: Uri ng tubo o spiral coils;

Isawsaw ang tubo at sukat ng temperatura na tubo;

Shaft, Couplings at pinagsamang stirring paddle impeller;

Distributor ng gas. spargers & baffles;

Opsyonal para sa Pressure Vessel

Full Jacket/ Half-pipe jackets/ Dimpled jackets;

Uri ng ulo: Semi-elliptical/ Dished/ Hemispherical/ Flat;

Paputok na Clad Steel para sa mga kondisyon ng mataas na presyon ng anti-corrosion.

Mga pagtutukoy

PANGUNAHING ESPISIPIKASYON | |

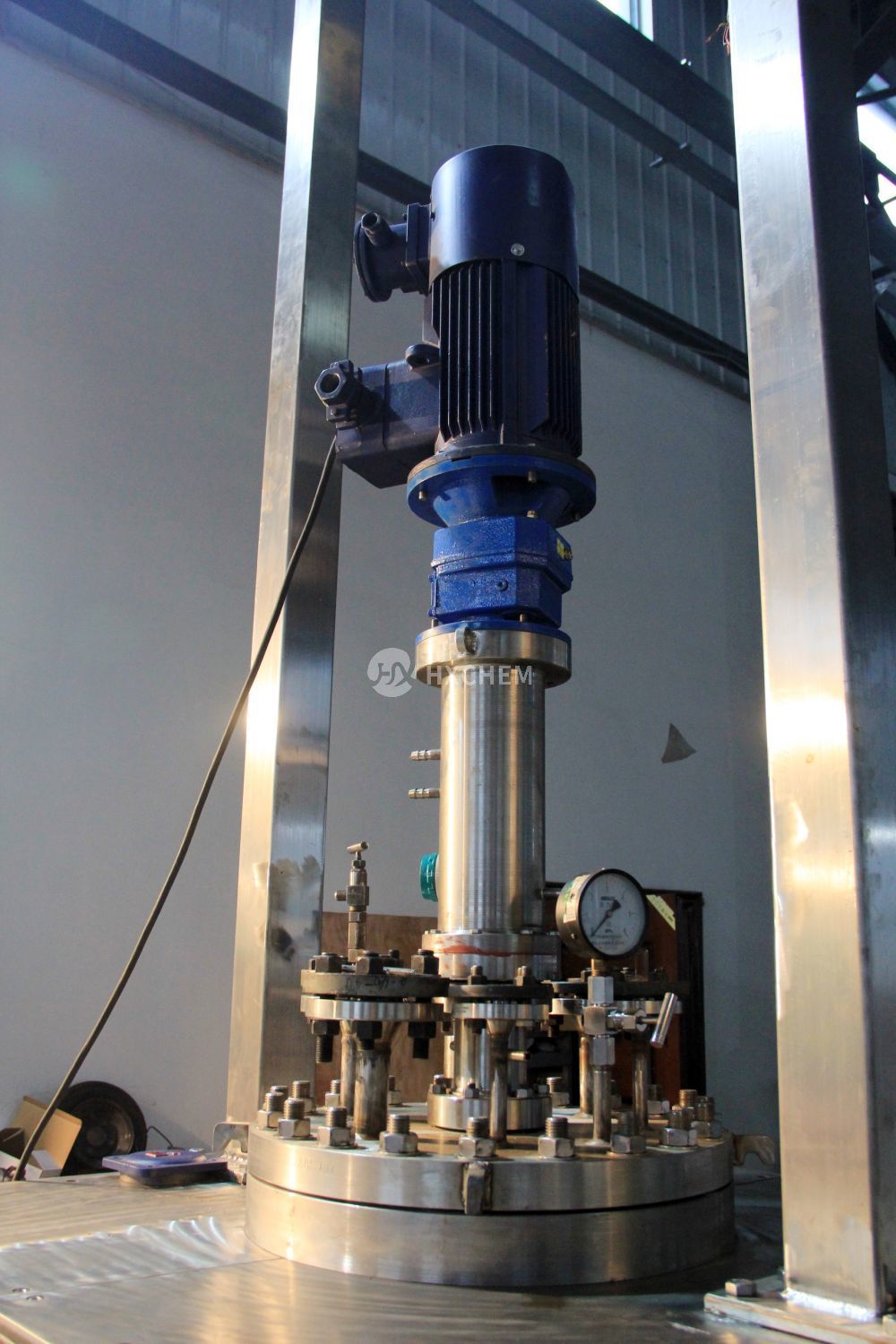

Modelo | FCH1000~20000L |

Kabuuang volume | 1000~20000 litro |

Presyon ng disenyo | 10~150bar |

Temperatura ng disenyo | 0~350 ℃ |

Materyal ng sasakyang-dagat | Karaniwang SS304/SS316/Solid o clad na bakal SS2205, SS321, C-276, nickel, titanium, zirconium |

Motor | Explosion-proof DIICT4/ 7.5-90kW |

Bilis ng paghalo | 0~350rpm |

Paraan ng pag-init | Langis, singaw at electric heating |

Paraan ng paglamig | Panloob na spiral coils o cooling tube condenser |

Uri ng jacket | Conventional/ Limpet coil/ half pipe |

Pagtatatak ng agitator | Zero leakage magnetic drive couplings |

Uri ng pagpapakilos | Hollow shaft na may gas induction impeller |

Gasket | Spiral wound metallic gasket |

Panloob na mga kabit | Termino. sensor, Dip tube, Baffles, Cooling coils, Gas distributor |

Tandaan: Ang data at detalye ay maaaring baguhin at i-customize bilang mga kinakailangan | |

Kategorya ng produkto

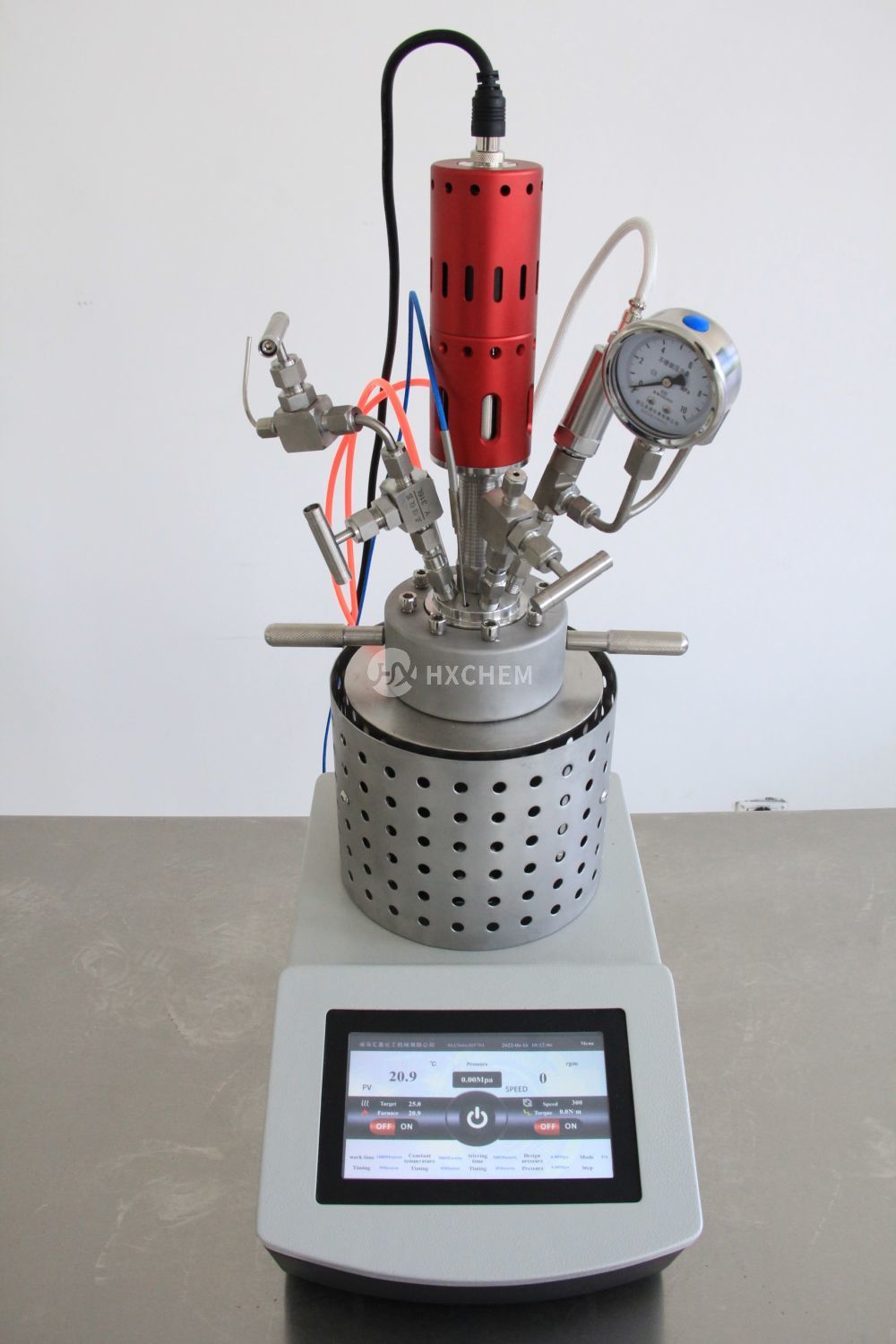

√ Bench top hydrogenation reactor (100ml-5liters)

√ Lab hydrogenation reactor (100ml-5liters)

√ Lab hydrogenation reactor na may lifting (5liters- 50liters)

√ Hydrogenation pilot plant (50litro- 500lits)

√ Industrial hydrogenation reactor (>1000litro)

Mga Kaso ng Produkto

Bench top hydrogenation Reactors / 100ml, 200ml, 500ml / 0-100bar/ 300C

GSH hydrogenation Reactors / 100ml-2liters/ 0-100bar/ 350C/ SS304/ SS316L

Mga Hydrogenation Reactor na may takip na nakakataas at nakakababa, ang katawan ng sisidlan ay maaaring paikutin.(100ml-5liters)

Mga Hydrogenation Reactor na may mabilis na bukas na aparato (100ml-5liters)

Mga Hydrogenation Reactor na may takip na nakakataas

10litrong Hydrogenation Reactor / 0-100bar/ 350C/ SS316L

20lits Hydrogenation Reactors

50litrong Hydrogenation Reactor

50L-500lits Hydrogenation Reactor

100L-1000lits Hydrogenation Reactor/ C276 hydrogenation reactor

1000L-3000lits Hydrogenation Reactor

5000L-10000lits Hydrogenation Reactor

10000L-20000lits Hydrogenation Reactor

20000L-30000lits Hydrogenation Reactor